DI Gottfried STEINER

- Founder

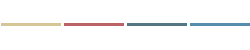

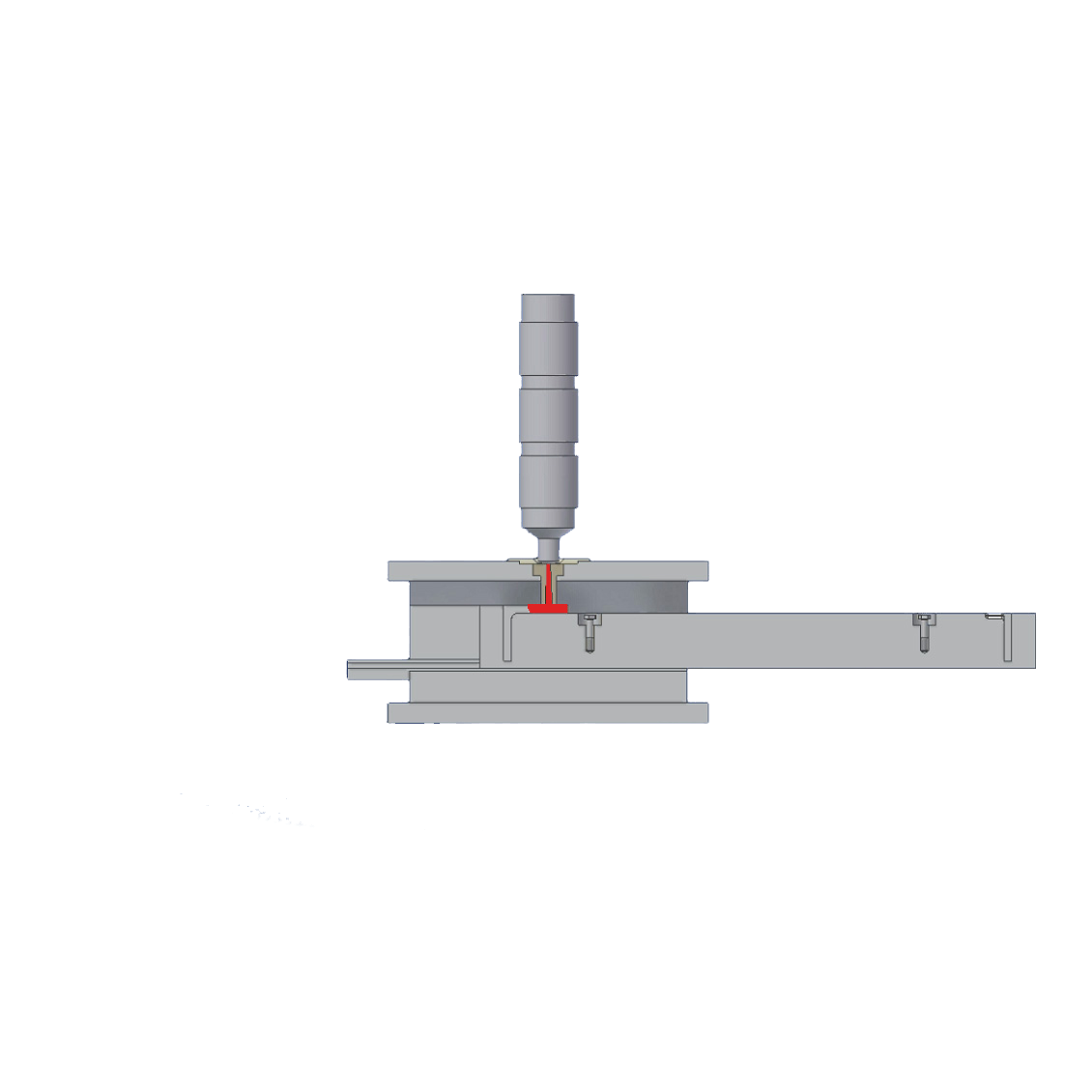

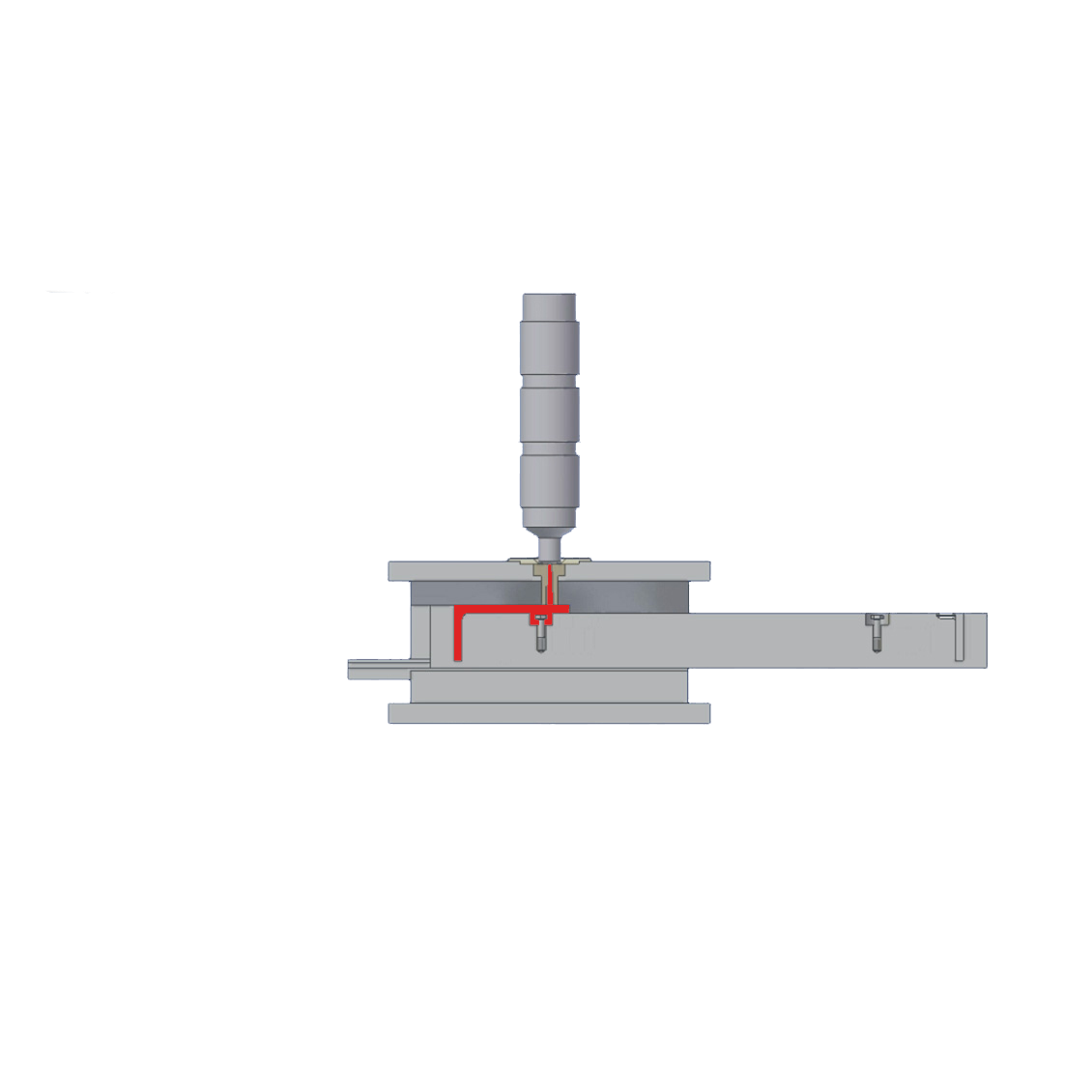

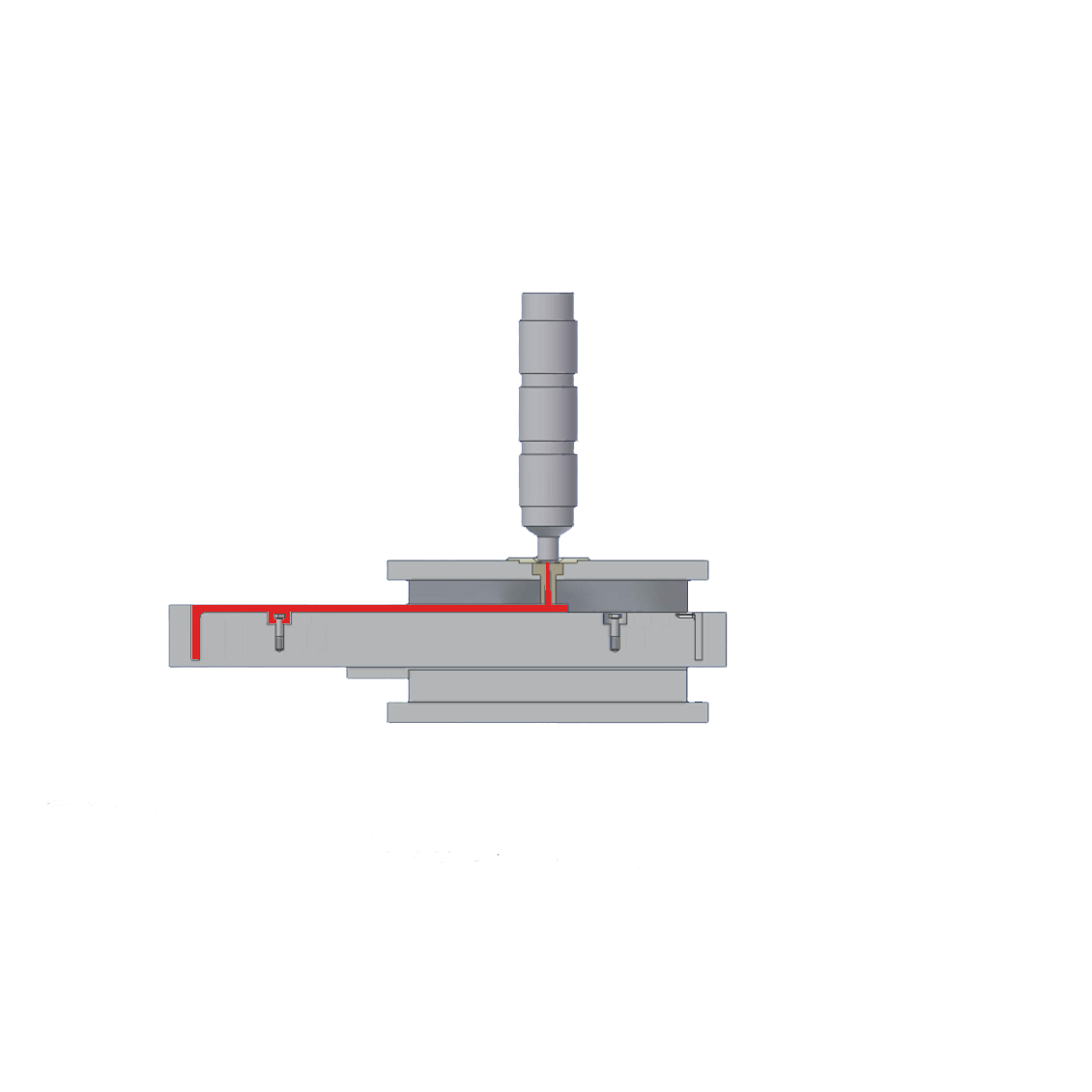

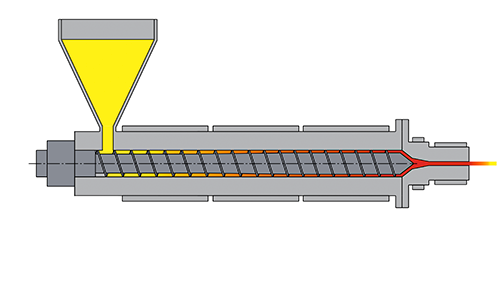

INJECTION MOULDING

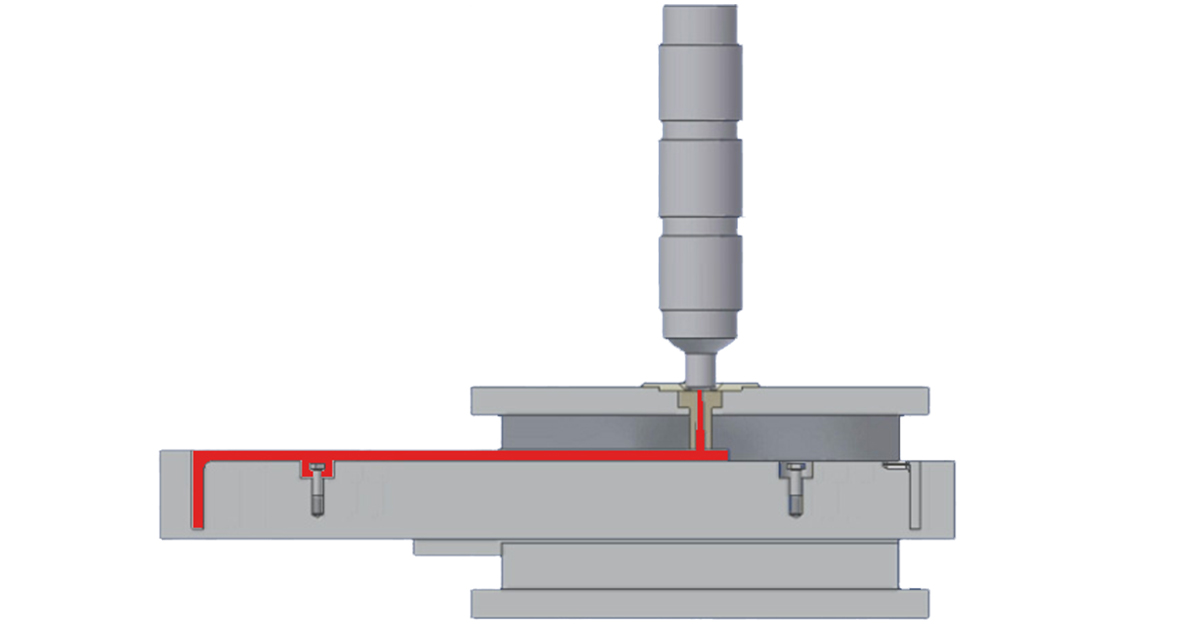

PRINCIPLE

EFFECTIVENESS

60%

reduced

investment costs

Using this technology for innovative new products does not only enable you to increase your production capacities but also to reduce the facility costs to almost the half.

20%

lower

manufacturing costs

Better quality, the production costs being lower - optimized processes and production methods enable you to increase the economic efficiency of your innovation and company.

40%

higher productiveness

The revolutionary EXJECTION Endless Technology makes it possible to produce much more components within the time unit than at the conventional injection moulding process.

EXtrusion

inJECTION

EXJECTION

Experience the advantages firsthand and seize the opportunity:

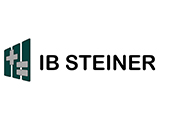

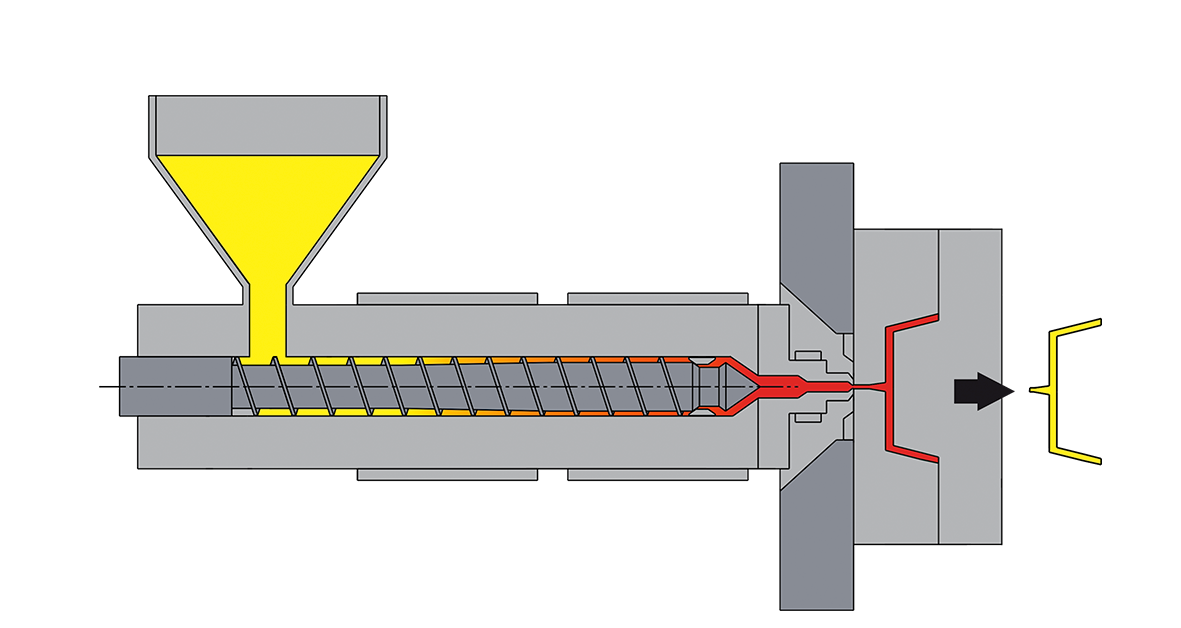

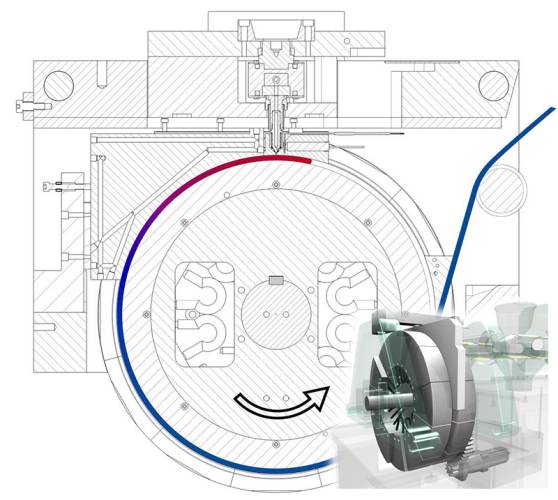

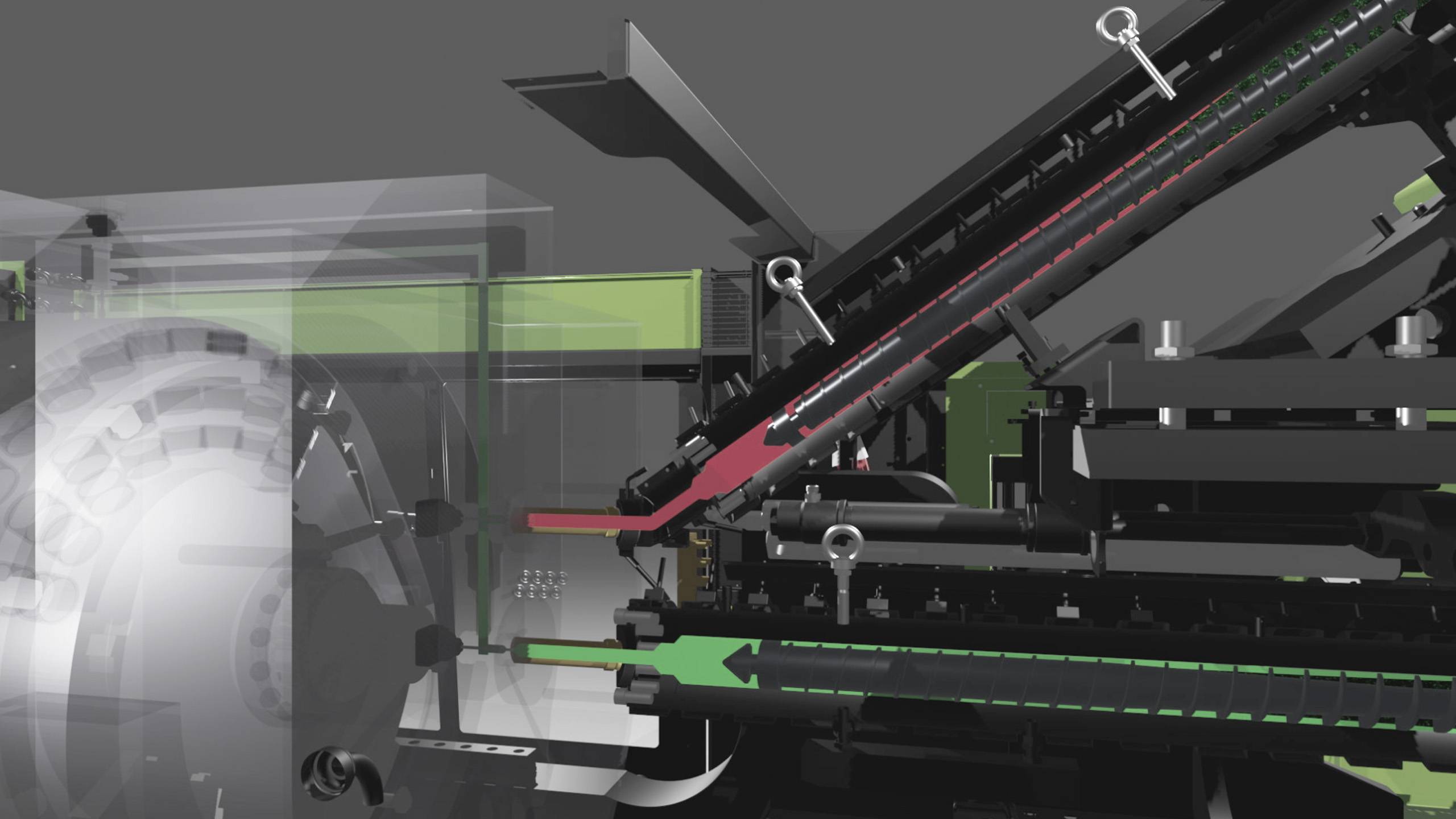

EXJECTION systems deliver impressive results, manufacturing exceptionally long components with minimal clamping forces and significantly reduced energy consumption. By incorporating two-component injection molding systems with alternating injection units, the potential applications of this technology have expanded significantly.

Using a rotational mold that enables simultaneous injection, cooling, and demolding, components can now be produced endlessly from the roll. This opens up unparalleled production capacities and possibilities, allowing you to embrace this innovative technology and benefit from the numerous advantages that EXJECTION has to offer.

Alternating Injection Units

Rotating Mould Cavities

Continuous process control

Experience EXJECTION

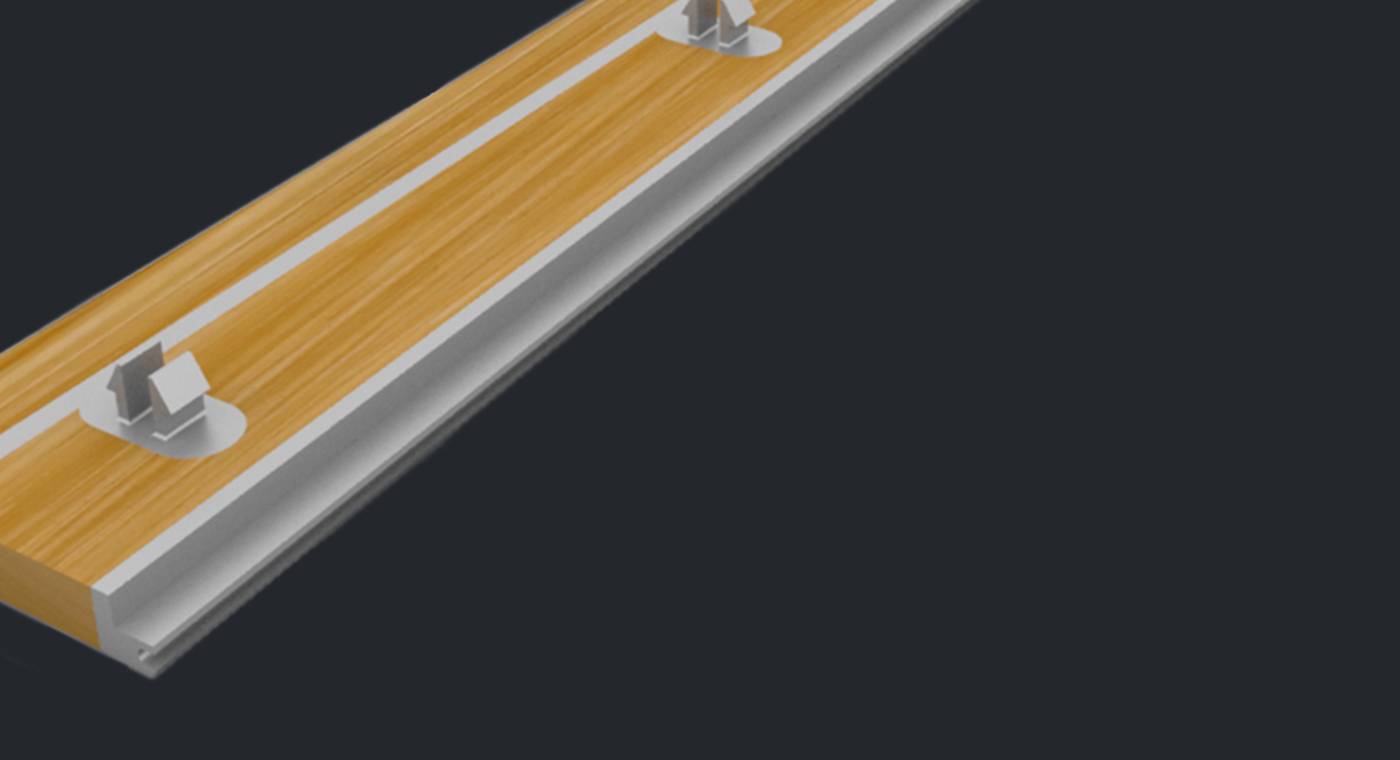

and perfection in light. At Vossloh Schwabe - Light Solutions, this is made possible by EXJECTION. See it for yourself...

Which geometries are practical?

Basic target of this technology is the production of long and profiled components. This defines the following basic features:

- END CAPS OR SIMILAR ARE REMOVEABLE/li>

- SURFACES WITH 3D-STRUCTURES

- STRAIGHT COMPONENT IS DEMOLDABLE

Which materials are processable?

As this process is closely related to conventional injection moulding, basically you can use any material which is processable on common injection moulding machines. 3 facts are to be considered:

- VISCOSITY OF MATERIAL

- KNOWN RULES FOR COMPONENT DESIGN

- TYP OF MATERIAL & WALL THICKNESS

Your way to innovation!

From the feasibility study to series production, we offer you a network of competent partners. Upon your request, the feasibility study will be made. This study will end up in a concept study before main development begins.

USAGE RIGHTS

ENGINEERING

REALIZATION