THE IDEA

Fundamental objective for the development of a new process is the production of long profiles and bars with functional geometries and structured surfaces of thermoplastic materials. Given the two standard methods injection molding and extrusion to be advantageously combined.

Project Start made by a

Feasibility Study

The terms “EXJECTION” and “ExM” (abbreviation for EXJECTION Moulding) are granted trademark rights with the Registry Numbers 219 999 (EXJECTION) and 220 000 (ExM) by the Austrian Patent Office. The positive results of a systematic approach and basic process development lead to the filing for a patent for the process. In addition, proprietary rights are claimed for the moulds and the components manufactured by using the new process. In order to assess the basic technical and economic feasibility, a feasibility study is made with the support of FFG (“Forschungsförderungsgesellschaft mbH” (Austrian Research Promotion Ltd.).

Start of Research Project

The extremely positive results of the feasibility study lead to the start of the research project EXJECTION. The project lasting for several years is co-funded within the start-up initiative by FFG (“Forschungsförderungsgesellschaft mbH” (Austrian Research Promotion Ltd.) in Vienna/Austria and SFG (“Steirische Wirtschaftsförderungsgesellschaft” (Styrian Research Promotion Ltd.) in Graz/Austria. The multi-anual project has a project budget of Euro 0.7 million and is borne by IB STEINER and HYBRID COMPOSITE PRODUCTS GmbH, which is established in September 2005, both companies being based in 8724 Spielberg/Austria.

Putting Research Mould into Operation

An important milestone consists in putting the research mould, which has been built by CAD-PLAST in the laboratory of ENGEL Austria GmbH in 4311 Schwertberg/Austria, into operation. Before this first process analyses were made by using a test mould provided by HTBL Kapfenberg. The first EXJECTION components are manufactured. The process is acknowledged in its function. Building of the research mould ready for series production has been supported by the Special Steel Corporation BÖHLER-UDDEHOLM, the coating specialist OERLIKON BALZERS COATING, both Kapfenberg/Austria, as well as by the manufacturer of gauges HASCO, Guntramsdorf/Austria, and KISTLER Company, Winterthur/Switzerland. Important process relevant components of the EXJECTION mould can favourably be integrated in an injection moulding machine. This increases economic efficiency in terms of the scope of investment and manufacturing costs even more.

Grant of patent AT 500 932 B1

Developed by DI Gottfried STEINER

Demonstrating Suitability for

Series Production

For the first time EXJECTION components with a wall thickness of 1.2 mm and a length of 930 mm are manufactured in a high quality by using the rebuilt research mould. Thus suitability for series production of the EXJECTION Process is demonstrated! Systematic process analyses on an ENGEL e-motion injection moulding machine show the expected good influence on the process. Different types of thermoplastics are processed by means of the new process. There always is the same result, which is extremely positive: The quality of the components meets the high market requirements. Serveral materials got tested, such as ABS, SAN, PMMA, IONOMER, PC, TPU, PBT, PA and PP.

Exhibition Highlight @ K2007

EXJECTION is ready to go into production

Design and Production of the EXJECTION mould "CONTROL LEDGE"

Based on the general agreement between the internationally successful German manufacturer of injection moulding machines for plastics ARBURG for cooperation in the field of the EXJECTION technology the cooperation yields first results. For the presentation of the EXJECTION technology at the ARBURG Technology Days from April 3rd to 5th, 2008 at the ARBURG head quarter in Loßburg / Germany the design and production of an EXJECTION mould at the latest state of the art has been agreed and promptly started. It is common goal of the cooperation to apply the mould for manufacturing the technically demanding component “CONTROL LEDGE” on a competitive functionality level. Main focus of the development team will be laid on proofing the process capability while producing high quality parts.

Premiere for EXJECTION

on the ARBURG ALLROUNDER 375V

Experience EXJECTION Live !

During the FAKUMA 2008 at Friedrichshafen ARBURG produced the new EXJECTION CONTROL RAIL on an ARBURG ALLROUNDER 375 V. The visitors could not only see the realization of a new mould concept with a horizontal running sledge, but also a drive unit of the sledge that has already been integrated into the injection moulding machine. The visitors response has been very good. Numerous new contacts have been made and several existing customers could have been welcomed at the FAKUMA 2008.

Technology Congress | Benefits

80 / 40 / 20

On June 18th 2009 for the first time IB STEINER presented the new innovative EXJECTION process. Therefore well-known representatives from the plastic industry met at Hotel Schloss Gabelhofen in Styria to get deeper knowledge of the EXJECTION process. The contributors covered relevant topics ranging from new, promising EXJECTION applications, over the current state of the art in the field of process simulation and the actual experiences with thermoplastic materials to first results from the field. The organizer, DI Gottfried Steiner, CEO of IB STEINER presented facts that backed up the superior capabilities of the EXJECTION process both economical as well as from a technical view.

Federal Award Consulting 2009

for IB STEINER

for IB STEINER

The Federal Award Consulting 2009 was presented by State Secretary Christine Marek in the Studio 44 in Vienna on November 23th, 2009. BMWFJ (Federal Ministry for Economic Affairs, Family and Youth) recognizes outstanding engineering performance by presenting the Federal Award in co-operation with ACA. It is IB STEINER that obtained the Federal Award for Engineering Consulting 2009 as a reward for the development of the EXJECTION Technology. This Award did not only emphasize the significance of the new technology but also placed the efficiency of the project partners in the limelight. Excerpt from the assessment made by the jury: ... On the one hand, energy efficiency is improved significantly (about 60 % of energy can be saved, which also has a correspondingly positive effect on the environment). On the other hand, lower investment costs (approx. 40 % as compared to conventional injection moulding machines) also help to lower the manufacturing costs for the plastics parts manufactured by using EXJECTION. In the interview with ACA, DI Gottfried Steiner explained, "Innovative technologies enable us to remain competitive on the world market. This plastics and innovative manufacturing technologies are very important for our future in the heart of Europe."

EXJECTION receives BRA.IN Award

The sector initiatives BRA.IN Construction Industry and BRA.IN Plastics Industry were launched in 2006 to promote research, development and innovation in these sectors. On 16 November 2009, the BRA.IN Day 2009 took place in cooperation with the WKO Upper Austria, at which a successful balance sheet was drawn up for the 3-year term. Best practice examples of innovative projects were presented and the funding opportunities that are still available were presented. A total of 862 organisations participated in the funded projects. The event ended with the awarding of prizes to excellent projects in various categories. The event was organised by Österreichische Forschungsförderungsgesellschaft mbH in cooperation with WKO Upper Austria.

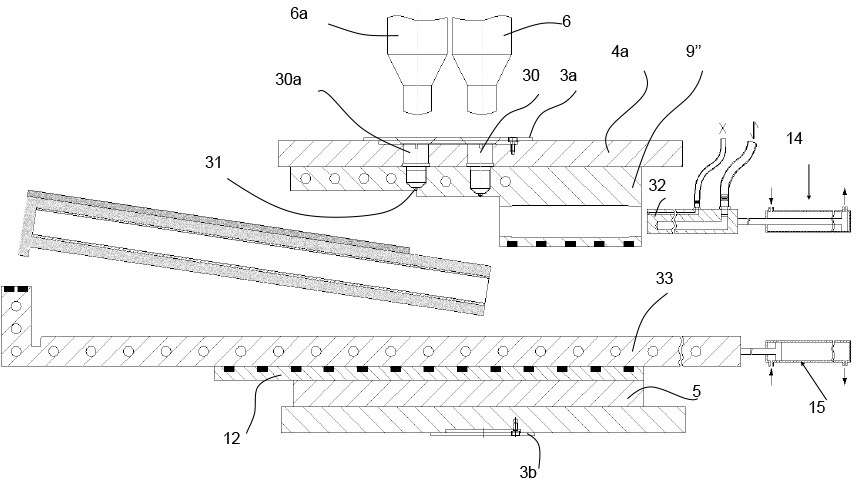

EXJECTION endless | Continuous Production

Continuous injection moulding becomes reality: Based on the idea of the moving cavity, the EXJECTION endless technology surmounts all limits so far set by the moulding cycle. The modular design of the EXJECTION endless mould makes it possible to demould already cooled and frozen segments of the moulded component while at the gate continuously new product is generated. Those segments of the cavity, where the component has already been demoulded, are transferred back to their initial position at the front end of the cavity. There they again generate new cavity, ready to be filled up again with melt. This way a discrete process becomes continuous. Development and realisation of the first mould, which has been brought into operation in July 2010, have been done in cooperation with the SAARGUMMI group, one of the leading suppliers of automotive sealing solutions and the Z-WERKZEUGBAU GmbH, one of Austria's leading mould makers. There the results of the development finally became reality. Nozzle insert and hot runner system were provided by the well established EXJECTION partner HASCO GmbH. Already the production of the very first 1.000 meters made clear that the process offers a very special charm.

Serial Maturity for Continuous Production

EXJECTION now continuous: 2007, INGENIEURBÜRO STEINER presented EXJECTION technology for the first time to the market, which makes it easy to manufacture products with 2 or 3 meters length on small injection moulding machines. In early July 2011, the first EXJECTION endless mould was operating on an injection moulding machine of ARBURG. This technology overcomes existing limits in injection moulding processes. For the frist time worldwide, continuous moulding is REALITY: production of components on a roll without dry cycle times for mold closing, mold opening and part removal. The process is entirely sufficient and reinforced already in first projects .

Reeling it off | EXJECTION endless

The areas of application for the EXJECTION endless process are manifold. Whether it is automotive, aerospace , electrical and electronics, construction or medical technology, for each sector it is easy to represented clearly the benefits. This applies to the component developer, who has access to unprecedented design possibilities and new functionalities, as well as to the business administration with lower manufacturing costs and higher production capacity. The development of EXJECTION towards continuous production shows the enormous potential in this still very young but already mature manufacturing process. The use of continuous technology is an excellent opportunity for plastics manufactorers to generate a competitive advantage and differentiate themselves by offering unique features in the difficult market of environment.

EXJECTION | symbolizes the future

LED Optics by Vossloh-Schwabe

Whenever an electric light turns on anywhere in the world, it's likely that Vossloh-Schwabe Germany GmbH has played a crucial role in ensuring smooth operation with just a flick of a switch. Based in Germany, Vossloh-Schwabe has been a member of the global Panasonic group since 2002 and is recognized as a technology leader in the lighting industry. The company's success is built on top-quality, high-performance products. They utilize EXJECTION technology for mass production and proudly inform their customers: "Through the implementation of the exjection method, a novel combination of extrusion and injection processes, we are now capable of manufacturing optics up to 2 meters in length with various photometric degrees of freedom."

EXJECTION Molding

comes into its OWN

Presented to the public for the first time by Engel at the K´2007 Show in Düsseldorf, EXJECTION technology has now established itself in the market across various applications. This success prompted SPE to publish the current state of this innovative process, which has been realized in different modifications. Particularly, the EXJECTION endless process represents a significant milestone for the next generation of injection molding. In a blog post by Jan H. Schut on the SPE website, he stated: "A decade after its introduction for molding long, thin parts from materials that couldn't be molded otherwise, Exjection is now being developed for high-volume applications in the medical, construction, and packaging industries. Its current advantages for both individual and continuous parts include improved efficiency, cost savings, and enhanced part quality."

by Jan H. Schut, 2016

by Jan H. Schut, 2016

RubExject:

Production of Rubber Components

- FFG Project -

In 2017, the first worldwide production of rubber components using the EXJECTION process took place at the Institute for Injection Molding of Plastics at Montanuniversität Leoben, utilizing an adapted research model by IB STEINER on an ENGEL rubber injection molding machine. The FFG project "RubExject" involved the participation of SKF Sealing Solutions Austria GmbH, located in Judenburg (8750), as an industrial research partner. ELMET Elastomere Produktions- und Dienstleistungs GmbH, specializing in the construction of EXJECTION rubber molds, was acquired in Oftering (4064). By 2019, test components made of NBR and HNBR were to be produced using a dedicated EXJECTION test model. Simulation was employed to analyze and optimize the process conditions, with subsequent verification through real tests conducted on the EXJECTION system.

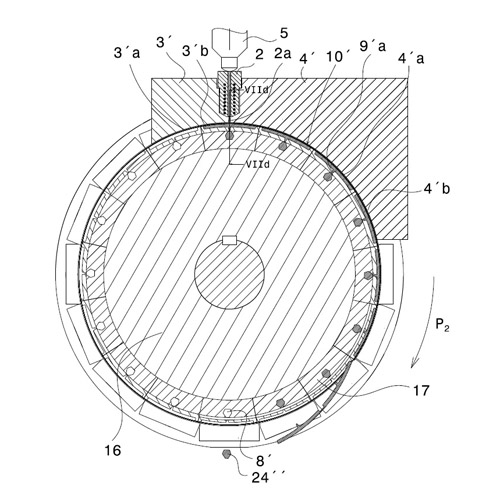

Patent for Continuous Injection Molding

The patent application for continuous injection molding, filed in 2017, will be granted in Austria in May 2018 and subsequently submitted for worldwide registration. Utilizing the exclusive EXJECTION technology, injection molded parts are produced within a rotating mold, similar to a bottling plant, with successive parts being released from the mold. The process parameters remain consistent for each component, ensuring uniform characteristics. With the elimination of traditional cycle times associated with the conventional injection process, productivity can be increased by up to 40%. Additional process steps, such as film insertion, do not impact the production rate. ENGEL has successfully implemented an EXJECTION system, enabling the realization of the continuous injection process with a rotating mold and confirming its performance. This marks the beginning of a new era in injection molding.

Excerpt from the Patent: Fig7

EXJECTION | endless

EXJECTION plant for EUROSPACERS

... with Mould Construction Competence from HAIDLMAIR

In 2019, HAIDLMAIR GmbH Werkzeugbau, located in 4542 Nußbach, acquired the expertise for constructing EXJECTION tools. During the symposium "40 years of HAIDLMAIR," the linear form of the EXJECTION plant from EUROSPACERS AB in Gothenburg, Sweden (41118), will be showcased. The ENGEL EVC 1340H/740W/300 combi injection molding machine, equipped with two injection units, enables operation with rotational molding for the continuous injection molding process. The EXJECTION software module integrated into the CC300 machine control system not only manages linear EXJECTION technology but also the EXJECTION endless technology, maximizing productivity according to the HAIDLMAIR philosophy. The rotomolding machine specifically designed for EUROSPACERS will commence series production in early 2020.

“STANDING STILL”

is not a step backwards

... but no progress either

The EXJECTION process and the associated technology are constantly being developed and are continuously moving towards a more efficient, sustainable future.

Keep yourself moving a well and stay uo to date with fast moving times and the state of technology.

Keep yourself moving a well and stay uo to date with fast moving times and the state of technology.