60%

reduced investment costs

Using this technology for innovative new products does not only enable you to increase your production capacities but also to reduce the facility costs to almost the half.

20%

lower manufacturing costs

Better quality, the production costs being lower - optimized processes and production methods enable you to increase the economic efficiency of your innovation and company.

40%

higher

productiveness

The revolutionary EXJECTION Endless Technology makes it possible to produce much more components within the time unit than at the conventional injection moulding process.

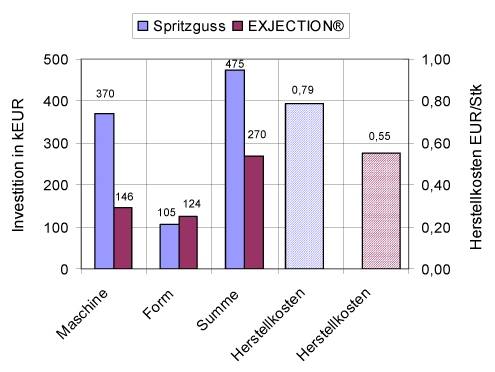

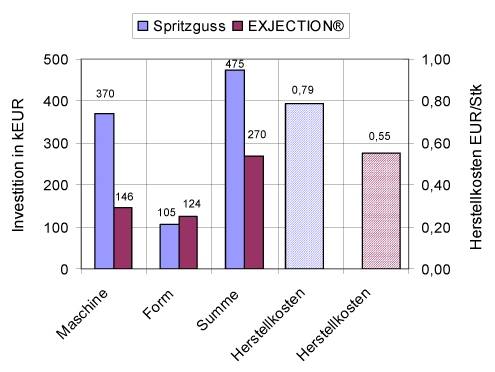

EXJECTION facilities that have already been implemented make it possible to manufacture very long components at small closing forces. As a comparison with the machines that are otherwise necessary for injection moulding of long components and have closing forces that are much higher, energy consumption can be reduced by approx. 60 %.As far as the investment volume is concerned, the average saving potential offered by EXJECTION amounts to about 40 % as compared to conventional injection moulding. This means that the the production costs will be made to be 20% lower by the new process.

The opportunities offered by continuous production using the EXJECTION endless process go far beyond this potential, which is already known. For the first time, it becomes possible to realize production of components on one injection moulding machine without the period of dry operation of the machine having an adverse impact on the overall cycle. Continuous production using endless technology no longer knows any unproductive opening and closing of the mould. It will only be necessary to invest the time that is necessary to fill the cavity. Thanks to this, energy efficiency of your company and production can be improved even more. This will have a positive effect on economic efficiency as a whole.

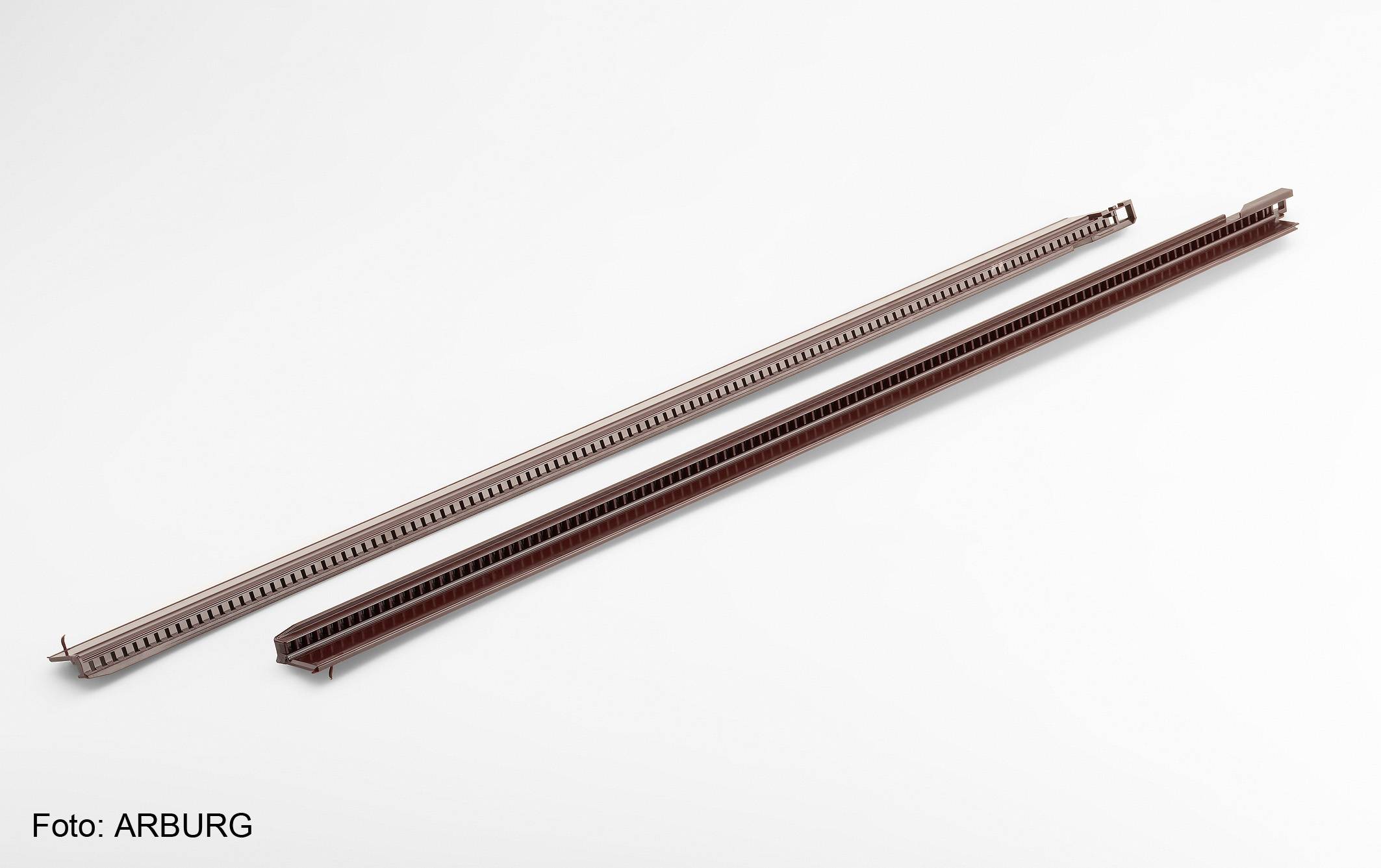

Trim Strip Example

The example "Trim Strip" can refute the following comparison:

Main dimensions: 1.440 mm x 30 mm x 19 mm (L x W x H)

Wall thickness: von 1,5 mm

Weight: 77 g

Material: ABS

Number of cavities: 1

Clamp force demand:

6500 kN with moulding -> 500 kN with EXJECTION

-

Low flowing distances

At the EXJECTION process, the molten mass need not bridge the flowing distance. It is the mould that will simply be shifted. It always is the current cross section that will be filled. And this will be done without hot-channel distributors and without cascaded control.

more freedom of design enabled by EXJECTION -

Minimum needs for closing forces

Short running distances lead to low pressure needs. Pressure will not act on the whole part but will only act where filling is just being done. Result: “a reduction of the needs for closing forces by up to 90 %”. Low processing pressures bring about innovative possibilities.

EXJECTION expands horizons -

Avoidance of Weld Lines

With EXJECTION, weld lines along the length of the component are a thing of the past. The mold cavity is continuously filled through a single connection.

EXJECTION will captivate you as well. -

Gentle processing of the molten mass

EXJECTION even makes it possible to back mould sensitive decorative materials. No matter whether it is a question of foils, textiles or organic materials, such as leather or wood. The connection will be established gently and without subjecting the decoration to shearing stresses. The risk of washing out is reduced to a minimum.

in-mould decoration using EXJECTION -

High-quality surfaces and decorations

This technology makes it possible to fill components in a manner that is as uniform as possible. Each area of a component will experience the same story. Thus EXJECTION guarantees the uniform optical appearance of metallic and effect pigments throughout the component length.

shining prospects offered by EXJECTION